Productronica 2023:

Tailored Die Attach Solutions at Booth B2-403!

+++ We would like to thank our many visitors, familiar and new faces, with whom we had many great conversations. We are already incredibly excited to be working with you to bring your product visions to life! +++

Finetech is a leading supplier of manual and automatic die bonders with more than 30 years of experience in high-precision micro assembly and advanced die attach.

In close cooperation with our customers, we create tailored process and equipment solutions for individual customer requirements. The modular die bonder hardware and software enables customized machine configurations that can be expanded and prepared for new challenges at any time.

Thanks to our “prototype-to-production” approach, R&D processes can effortlessly be transferred from development to production for integrated, flexible and cost-efficient product development.

Let’s find out how our team can support your project with long-standing expertise, innovative technical solutions and 100% commitment to the challenge.

+++ We would like to thank our many visitors, familiar and new faces, with whom we had many great conversations. We are already incredibly excited to be working with you to bring your product visions to life! +++

Finetech is a leading supplier of manual and automatic die bonders with more than 30 years of experience in high-precision micro assembly and advanced die attach.

We create tailored solutions for individual customer requirements. Our “prototype-to-production” approach enables integrated, flexible and cost-efficient product development.

Quick machine setup and clever material handling and cleaning solutions reduce preparation time by up to 50%.

Master the fine pitch micro Indium bump interconnect flip chip bonding process to manufacture state-of-the-art products more efficient than ever.

#Co-planarity #Accuracy #Cleaning #OxideReduction #Handling #InterconnectQuality #Throughput #Yield #CostPerBond #ConnectedPixelRate

Have you considered manufacturing the CoC/CoS diode lasers for your laser modules yourself? Partner with Finetech and take the development and production of your laser modules into your own hands.

Your benefits: technology sovereignty, customizability, cost reduction, increase in reliability and quality.

Manufacture diode lasers with specific properties that are unique on the market.

#Photonics #Optoelectronics #LaserBarBonding #SingleLaserBonding #LensPlacement #FiberOpticsAssembly

A laser pulse is used to activate or ignite reactive multilayer systems (RMS) such as preforms or nanofoils.

It is a very efficient bonding technology and perfectly suited for automated multi-chip module assembly.

#ReactiveSoldering #Nanofoil #ReactiveMultilayerSystem #Preform #LaserActivation #MultiChipModule

For optimal results in terms of process efficiency, reliability and yield, we keep improving and innovating on all process parameters. Together with our customers, we love to push the limits of what is possible.

Some of the recent fields of innovation include improved machine and process parameters (optimized force and temperature control, thermal drift control), process modules (plasma cleaning, UV curing, ultrasonic bonding, laser activation, enhanced process gas implementation, material cleaning and handling, as well as tooling (3D printed designs, special coatings and materials, application-specific solutions).

How can we take your assembly processes to the next level?

Based on this, we develop optimal process solutions for a wide range of different applications together with customers from a wide variety of industries.

These include die attach and packaging of Photonics / Silicon Photonics components as well as Sensors and Detectors, Electronic Devices, Actuators, Displays, Fluidic Devices and many more.

We look forward to learning more about your unique application challenge during Productronica 2023.

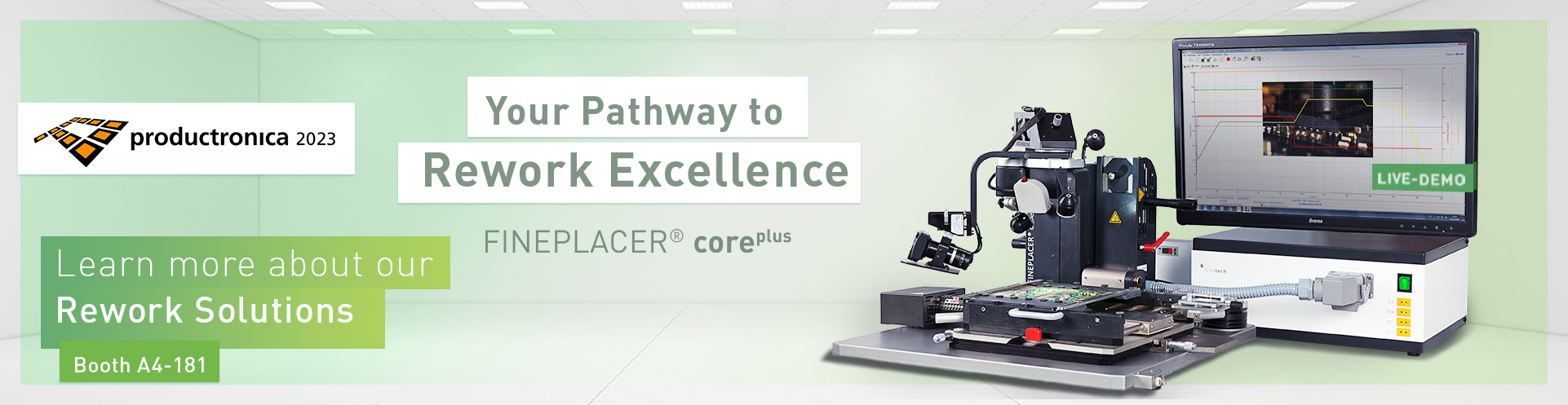

FINEPLACER® femtoblu

The Efficient Solution for Photonics Production

An automated micro assembly cell with placement accuracy of 2 µm @ 3 Sigma and ultra-low bonding force capability.

The modular FINEPLACER® femtoblu can be individually configured and upgraded in-field to support additional applications and technologies in the field of photonics.

FINEPLACER® femtoblu

The Efficient Solution for Photonics Production

An automated micro assembly cell with placement accuracy of 2 µm @ 3 Sigma and ultra-low bonding force capability.

The modular FINEPLACER® femtoblu can be individually configured and upgraded in-field to support additional applications and technologies in the field of photonics.

FINEPLACER® pico 2

The Most Powerful Tool for Lab & Research

Our multi-purpose, manual die bonder with placement accuracy down to 3 µm. Ideal for fast and flexible product development and prototyping in R&D labs and universities.

The FINEPLACER® pico 2 offers an outstanding return on investment and is a natural starting point on the journey from concept to final product.

NEW: Integrated Die-Eject Module

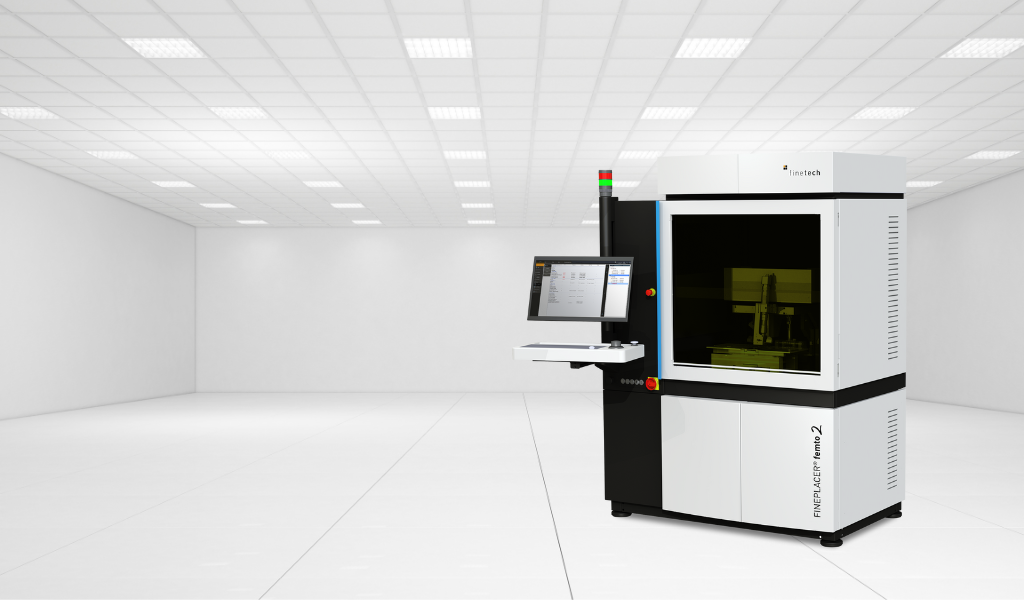

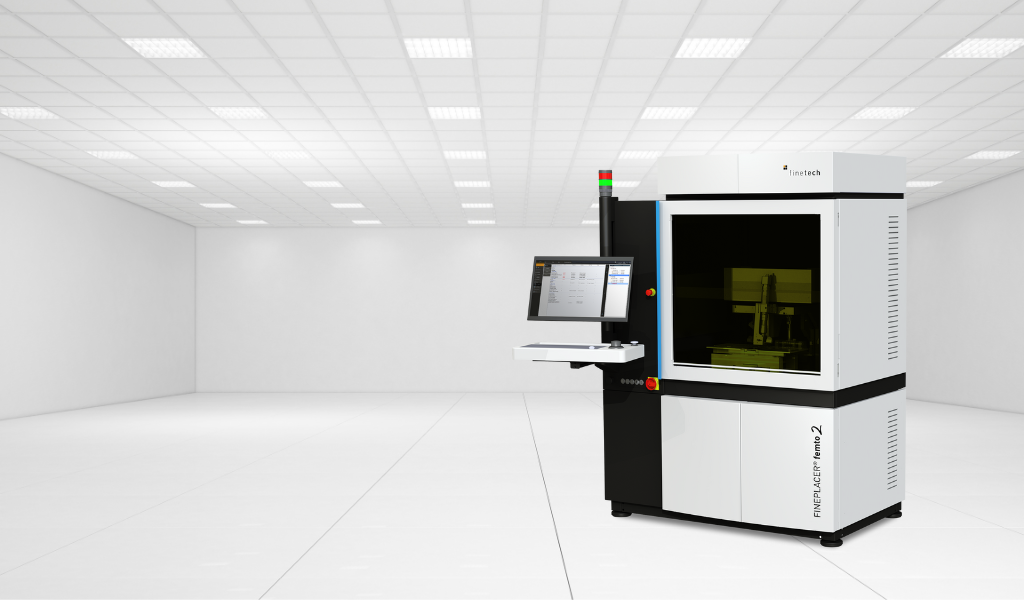

FINEPLACER® femto 2

Advanced Automated Sub-Micron Bonder

Fully-automated die bonder offers unrivaled flexibility for prototyping & production environments.

The modular design of the automated die bonder FINEPLACER® femto 2 can be individually configured and retrofitted at any time to support new applications and technologies.

FINEPLACER® femto 2

Advanced Automated Sub-Micron Bonder

Fully-automated die bonder offers unrivaled flexibility for prototyping & production environments.

The modular design of the automated die bonder FINEPLACER® femto 2 can be individually configured and retrofitted at any time to support new applications and technologies.

✓ Expertise Beyond Measure: We are the die bonding experts who thrive on challenges. Your obstacles become our opportunities to help you, and together, we achieve remarkable results.

✓ Tailored Solutions: No two projects are the same. That’s why we offer customized solutions, providing you with machines and processes designed to fit your unique requirements.

✓ From Concept to Market: Our “Prototype-to-Production” approach enables fast, low-risk flexible product development and seamless process transfer from R&D to production.

✓ Accuracy Redefined: For us, accuracy goes beyond placement accuracy. It’s a commitment to perfection in every aspect of die bonding.

✓ Lifelong Flexibility: Our support doesn’t end with a sale. We are dedicated to offering flexibility throughout your machine’s lifecycle, ensuring it adapts to your changing needs.