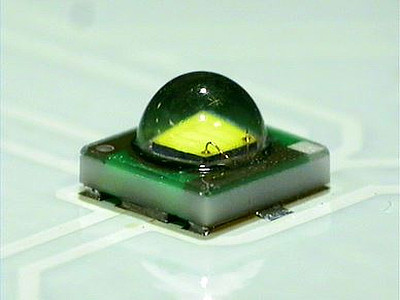

Thermo-sonic bonding is the process of flip chip bonding a die to a substrate using gold as the interconnect while avoiding high temperatures.

Sounds pretty straight forward, but why then, is the process window so small regarding die size compared to surface area of gold, versus I/O count of the chip to substrate?

When bonding large die to a substrate with high I/O count there are some serious process issues that must be addressed for a successful bond.

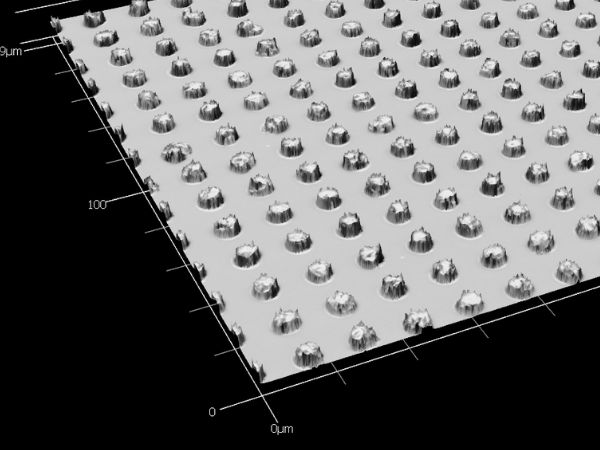

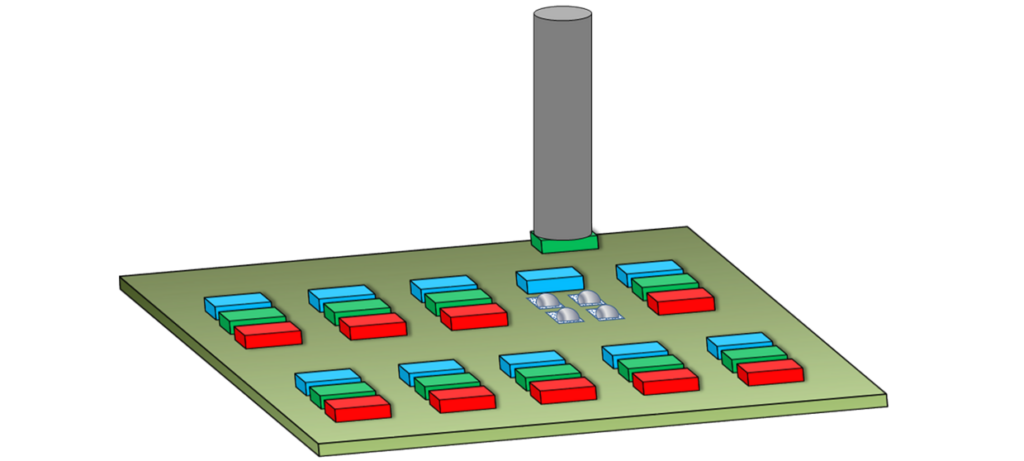

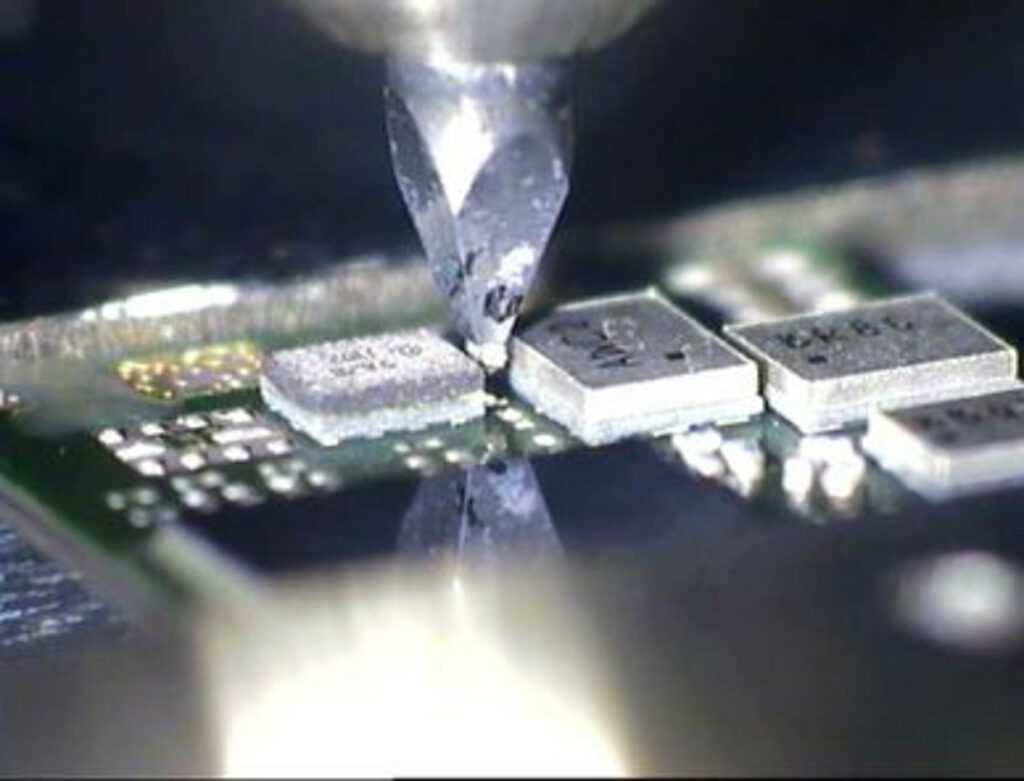

The goal of thermo-sonic bonding, for the most part, is to “scrub” a gold bump into a gold pad, creating an electrical connection. When creating a profile, there are a few parameters needed –

- Ultrasonic energy, measured in Watts or Milliwatts

- Force, measured in Newtons (N)

- Temperature

- Time measured in seconds or milliseconds

As the I/O count increases, so does the force, time and ultrasonic energy. There is a simple calculation to find a starting point. Finding the optimum vacuum to hold the die during the bonding process is not as simple. The die has to be held by vacuum over the energy and the force. If the balance of force/energy compared to the vacuum is incorrect, the vacuum will not be sufficient and the die collet will begin to move on top of the die. This results in no energy being transferred from the interconnect of the die to the substrate. If a process gets to this point, it is close to the physical parameters that make thermo-sonic bonding a real challenge.

Imagine a very large die…say 25 x 25mm with 500 I/O’s. Imagine the amount of energy, force needed to bond this size of die. Imagine how much vacuum you would need to hold the die over the force and energy. It’s not easy. This is a process issue found throughout the industry. The right equipment combined with the right process parameters can solve this problem. If you want to learn more about solving challenges with thermo-sonic bonding, contact us.

Stay tuned for Part 2 where we will explain the opposite problem, small die with few I/O’s and how the processes compare.

09/08/2014, created by: Robert Avila