Founded in 1992 as an East Berlin “start-up”, today Finetech GmbH & Co. KG is a leading global manufacturer of placement, assembly and rework systems for customers in the microelectronics industry. This year, the company celebrates its 30th anniversary.

It all started in a rented apartment in Berlin-Friedrichshain: shortly after German reunification, an East Berlin engineer – owner of an ingenious patent on how to align electronic components with each other with high precision – and two colleagues built and marketed the first placement and assembly system based on the so-called FINEPLACER® functional principle. The original FINEPLACER® was an amazingly simple platform with a swivel arm and a fixed optical beam splitter. Then and now, the motto was “simply accurate”, which is still the brand essence of Finetech.

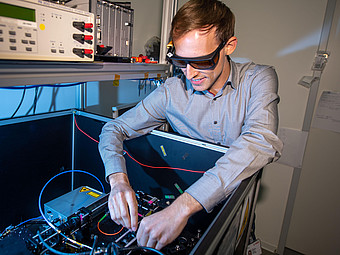

With the FINEPLACER® systems, Finetech set new standards in precision assembly of semiconductor products. Continuously improved and updated over the years, the placement and assembly systems today master complex micro assembly applications with a placement accuracy of up to 0.3 micrometers. Flexible expandability via function modules enables the use of a wide range of bonding technologies, and ensures that the machines can be adapted to new tasks throughout their entire service life. Quality optics developed specifically for Finetech, dispensing technology and the very stable design of the machines enable particularly accurate and reliably repeatable assembly processes at all times.

This is complemented by a second business area. Finetech’s so-called hot gas repair systems are also based on the FINEPLACER® principle and are powerful solutions for the professional rework of SMD assemblies. They combine all the capabilities for the rework of modern electronics, such as extremely precise thermal management, adapted soldering tools and the integration of diverse support processes. Only in such a way can individual components, some of them being barely larger than a grain of sand, be reliably desoldered and soldered in place even on extremely densely populated circuit boards.

Innovations today for the world of tomorrow

In the segment of die bonder systems for research and development, Finetech is now the market leader and supports customers of all sizes and industries on their way from the concept to the production of innovative semiconductor products. To this end, the Berlin-based company brings people and technologies together, advises researchers, developers and production managers worldwide, and provides them with the appropriate tools to find technical solutions to the complex future issues of our time.

The main driving force for Finetech is to facilitate the development of innovative semiconductor products with integrated process and machine concepts for high-precision die attach applications. In order to support customers already in the development phase and to accompany them in the transfer of their processes to series production, Finetech has systematically expanded its portfolio of automated die bonders in recent years. Complementing the manual R&D equipment for laboratory and clean room, the semi- and fully automated production systems combine process flexibility, high accuracy and speed.

Finetech’s unique selling points: a cross-system machine architecture, standardized function modules and identical operating software on manual and automatic systems. This means that product developments from the initial concept to automated series production can be implemented completely frictionless within Finetech’s technological ecosystem. Finetech calls this approach “Prototype-to-Production”. The big advantage: technological hurdles and investment risks in the development of innovative semiconductor products are largely eliminated.

In close partnership

Finetech serves companies and organizations from a wide range of industries, including data and telecommunications, industrial semiconductor, consumer electronics, medical technology, aerospace, automotive, defense & security, and energy, as well as universities and institutes. The worldwide installed base of machines includes start-up companies as well as international corporations, the R&D departments of major OEMs, publicly funded laboratories, and a variety of academic institutions.

For this, Finetech relies on a trusting and long-standing partnership with its customers – many have grown together with the Berlin-based company and have implemented countless projects on Finetech machines.

As the customers’ needs are highly individual, off-the-shelf solutions are not expedient. In Finetech’s Application Center with its state-of-the-art cleanroom technology, the feasibility of processes is evaluated on the basis of customer samples and machine configurations tailored to the customer requirements can be thoroughly tested.

Based in Berlin, at home in the world

As a regional employer, Finetech is firmly rooted in its home in Berlin-Marzahn. Since 2015, Finetech has been operating from its own state-of-the-art production and development center in the CleanTech Business Park, a location for clean technology companies promoted by the state of Berlin and, at 90 hectares, the capital’s largest inner-city industrial park in the future. Thanks to fast transport routes, a well-trained workforce and intensive networking opportunities with Berlin’s research landscape, Finetech finds ideal conditions here for manufacturing and distributing its high-precision placement and assembly systems and serving its global customer base.

At the company headquarters in Berlin alone, highly qualified engineers, designers, software developers, skilled workers and other specialists from more than a dozen nations are working toward the shared goal. At the same time, Finetech Berlin is part of a cooperative training network, where every year young people learn their craft in various professions.

In addition to the headquarters in Berlin, Finetech has another development center in Dresden, sales & support centers in Asia and America, and a worldwide network of representatives. This enables Finetech to provide fast on-site service and personal advice at all times. For the last 30 years and also in the future.

Historic milestones

1992 – 2001

| 1992 | Foundation of Finetech Gesellschaft für Elektronik-Technologie mbH in Berlin-Friedrichshain |

| 1992 | Presentation of FINEPLACER “183”, later known as FINEPLACER® micro |

| 1995 | Development of COMISS (Controlled Mix Soldering System), still the basis of Finetech hot gas technology today |

| 1995 | FINEPLACER® pico for rework and bonding is introduced |

| 1997 | Presentation of FINEPLACER® lambda – first flip chip bonder with a placement accuracy of less than one micron |

| 1998 | Finetech becomes part of the Baumann Group of companies |

| 1999 | Finetech USA founded in Arizona |

| 2000 | Acquisition of Protec 21 GmbH in Dresden; becomes a Finetech R&D laboratory for automatic systems |

2002 – 2011

| 2004 | First time certification according to ISO 9001 |

| 2006 | Foundation of Finetech China in Shanghai |

| 2007 | Launch of FINEPLACER femto, the first Finetech bonding machine with a placement accuracy better than 1 micron |

| 2008 | Opening of Finetech USA East in New Hampshire |

| 2008 | Foundation of Finetech Malaysia (operating until 2021) |

| 2009 | Presentation of FINEPLACER® core, compact all-round rework system |

| 2010 | Acquisition of the German rework and dispensing specialist Martin SMT |

2012 – 2022

| 2014 | Market launch of FINEPLACER® sigma, a new generation sub-micron bonder |

| 2014 | Foundation of Finetech Japan |

| 2015 | Relocation to the company’s own production and development center in Berlin-Marzahn |

| 2016 | Presentation of the FINEPLACER® femto 2, fully automatic sub-micron bonder |

| 2017 | Introducing FineXT 6003 and FineXT 5205, the first automatic Finetech bonding systems designed as gantry systems |

| 2019 | FINEPLACER® lambda 2 is introduced, successor to the legendary sub-micron Die Bonder for R&D |

| 2020 | Presentation of the FINEPLACER® femtoblu |

| 2021 | Presentation of the FINEPLACER® pico 2 |