Finetech, a leading provider of precision die-bonders, announces the Promex purchase of the FINEPLACER® sigma. This is the second FINEPLACER® system implemented by Promex, joining a FINEPLACER® pico system purchased in 2019. Finetech is excited to see how the new sigma system will enable Promex to expand manufacturing for their customers in areas such as automotive, biotech, medical and optical.

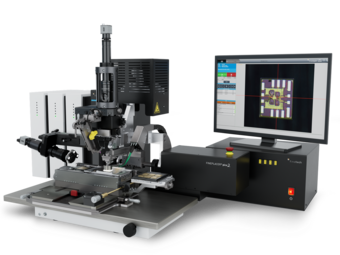

SANTA CLARA, Calif., Feb. 02, 2023 — Promex Industries, a Silicon Valley–based provider of advanced design, packaging, and microelectronics assembly services, today announced the next key addition to its die-bonding service capabilities: a Finetech FINEPLACER® sigma advanced sub-micron bonder. Designed to deliver high placement accuracy for an array of processes (flip chip, wafer-level packaging, package stacking, and chip-on-glass/flex/board, to name a few), the FINEPLACER® sigma system was received at the Promex facility in December.

The FINEPLACER® sigma purchase is the second Finetech system selected by Promex, joining a FINEPLACER® pico system purchased in 2019. The new FINEPLACER® sigma system delivers several features that will further benefit Promex customers seeking die bonding for precision bonding requirements in optical, medical, biotech, automotive, and other applications.

Combining sub-micron placement accuracy with a 450 mm x 150 mm working area and bonding forces up to 1000 N, the FINEPLACER® sigma system features a modular design for valuable flexibility. Modules can be easily combined or exchanged to pursue various projects within a single tool. Key technologies that can be performed, depending on the modules selected, include sintering, thermocompression bonding, ultrasonic bonding, eutectic soldering, adhesive bonding, and precision vacuum die bonding.

Placing small devices on large substrates is achieved via the FINEPLACER® sigma’s ultra-high-definition FPXVision™ vision alignment system. FPXVision™ allows the smallest structures to be viewed across the entire field of view, at the highest magnification, and enables pattern recognition with manual bonder alignment across a large bonding area.

“Choosing our next-generation sub-micron FINEPLACER® sigma illustrates the trust that Promex places in us and our bonding-technology expertise,” stated Neil O’Brien, General Manager of Finetech USA. “We look forward to continuing to work closely with Promex as they bring the sigma system online and are able to share the benefits with its vital customer base.”

“The FINEPLACER® sigma is a perfectly paired addition to our Finetech FINEPLACER® pico and extends our extreme placement accuracy and control to the next level,” said Chip Greely, vice president of engineering for Promex. “We’re excited about the additional capability and capacity we now have available to support our customer’s precision flip chip and placement needs.”

About Promex

Promex Industries, Inc. specializes in advanced design, packaging, and assembly services for key subsystems used in a wide range of applications, such as optical, photonics, diagnostics, life sciences, medical, and MEMS devices. The company is skilled at heterogeneous integration of tiny components with unique functionality and complex, custom, or detailed assembly requirements. Founded in 1975, Silicon Valley–based Promex provides design-for-manufacturing services coupled with materials-science expertise and broad assembly capabilities for small- to mid-volume onshore production. Services include RoHS-optimized SMT, wafer thinning, dicing, wire bonding, flip chip, and combining microelectronic and non-microelectronic components, provided in the company’s Class 100/Class 1000 cleanrooms. Promex holds a CA FDB license and is ISO 13485:2016 and ISO 9001:2015 certified and ITAR registered and follows IPC610 standards.