It’s always interesting to learn about the chemistries our customers will use in next generation bonding technologies. There is so much to take into account.

The diversity and properties of materials varies greatly — low or high viscosity, and thixotropic media are a few parameters that need to be addressed when selecting a material that will perform well in your application. More importantly is investing in equipment that allows you to step through the entire bonding process and build a profile that will ensure a seamless roadmap to your production process. Here is where Finetech can make an impact in your R&D efforts.

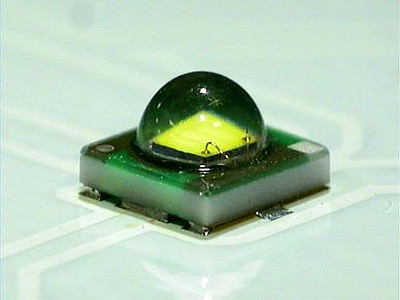

Take epoxy bonding for instance. For a growing number of assembly processes, adhesives are now the preferred material. This is based on an extended spectrum of applications and improved processing methods. Significant progress has been made to achieve stronger resistance against rough environmental conditions – such as extreme temperatures, air humidity and UV radiation – as well as better compatibility with other substances.

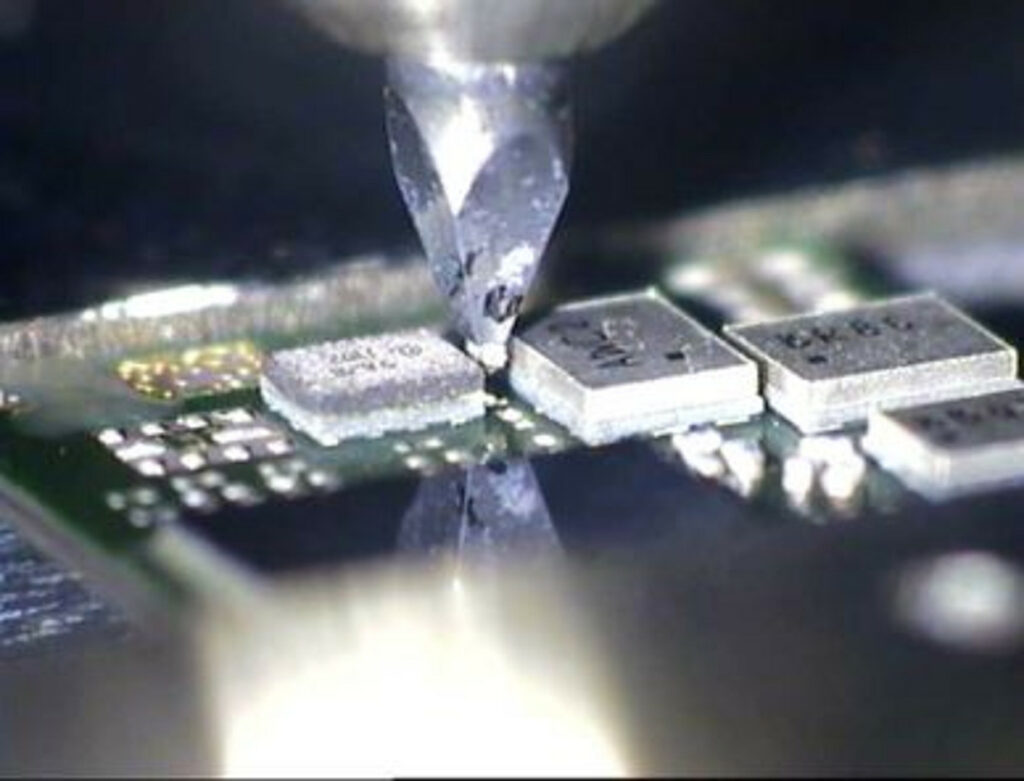

Design or application limitations can require adapted hardware and tooling solutions designed to apply such material. Flux trays, stamping tools, heated needles are some of Finetech’s die-bonding process accessories. However, it is the flexibility of Finetech’s table-top manual R&D die bonders that allow for users to conduct diverse tests with epoxy under various thermal conditions (i.e., top heat and bottom heat & UV) to understand how epoxies perform under a specific bonding conditions. Finetech’s side observation cameras record video and snap pictures of the entire bond process, capturing real-time validation of potential fillet results exposing die attach contamination or die lifting and cracking.

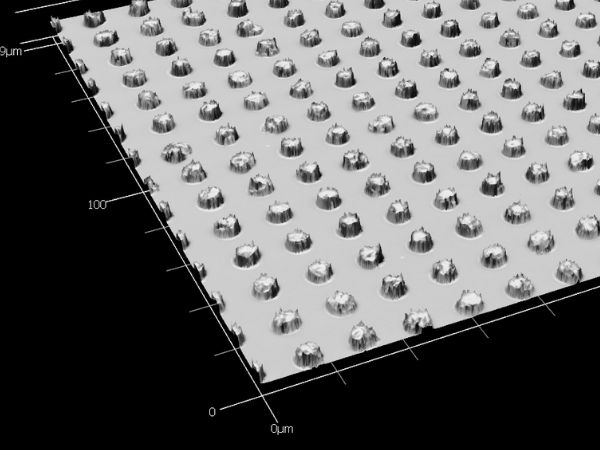

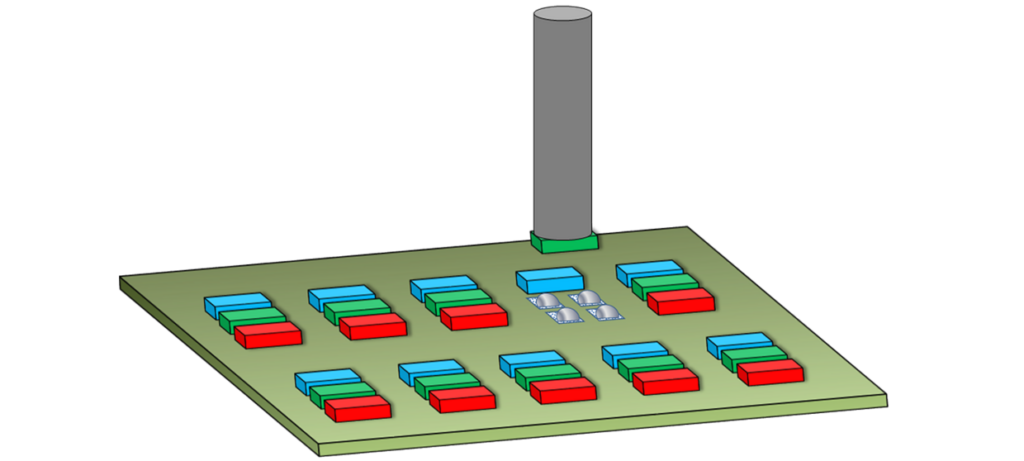

Finetech can provide automated and manual dispensing solutions to apply materials which can reproducibly apply glue with spot diameters of 200 µm and less. We can integrate time/pressure, Auger and jet dispensing – all on the same bonder.

In production environments, adhesives have become an essential material for mechanical, electrical, thermal and optical bonding and sealing. Glue is also used as a compensation plane for bonding partners with differing expansion coefficients.

Customers find that our bonders are extremely versatile when it comes to handling a wide range of materials, using various technologies.

05/15/2017, created by: James Bishop