With the help of a fully automated multi-chip bonder from Finetech, the Berlin-based laser specialists at Lumics have been able to improve reliability of their diode laser module manufacturing and to significantly increase production volume.

Lumics GmbH, founded in 2000 and member of B.I.G. Berlin Industrial Group, is a key player for design and manufacturing of diode lasers used in demanding medical, industrial and scientific applications. In-house capabilities range from chip level up to fiber-coupled diode laser modules and turn-key laser systems based on single emitter technology.

The product range comprises multi and single mode diode lasers available from 670nm to 1940nm, including the custom configurable LuOcean series and industry standard solutions.

The field proven lasers are offered with additional features allowing for adaptation to the most innovative applications in Medical & Life Sciences, Material Processing, Analytics & Sensing, Metrology, Telecommunication, Seeding, Pumping, Security, Illumination, and many more.

No longer enough

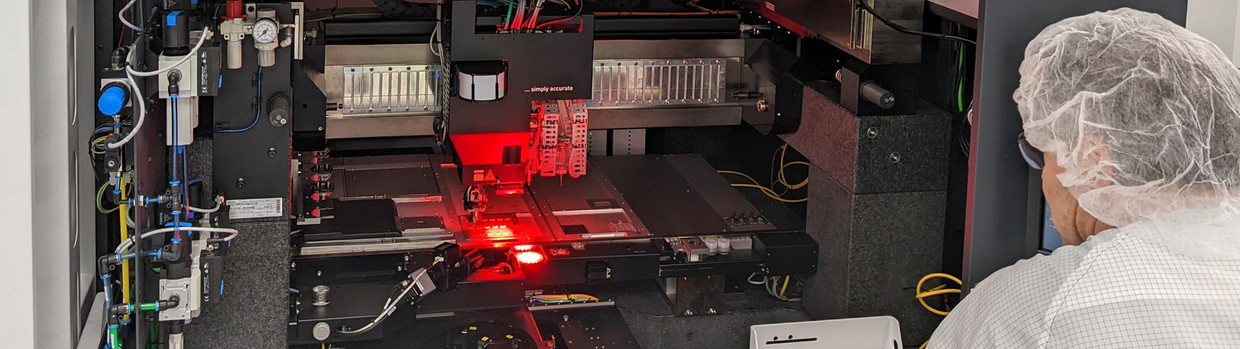

For the production of its diode lasers (laser bonding on submount and subsequent package assembly on a flatmount), Lumics previously used an older automated unit. However, the machine no longer met the significantly increased requirements at Lumics and also required frequent manual intervention due to poor image recognition and the inability to view the component to be assembled from below. Coordinates for placement had to be entered manually as offset values, and tool adjustment was also extremely time-consuming.

Since reliable production in larger quantities was difficult to realize, Lumics researched the automatic die bonder market for an alternative that would support the old system in the short term, with the intention to replace it later on.

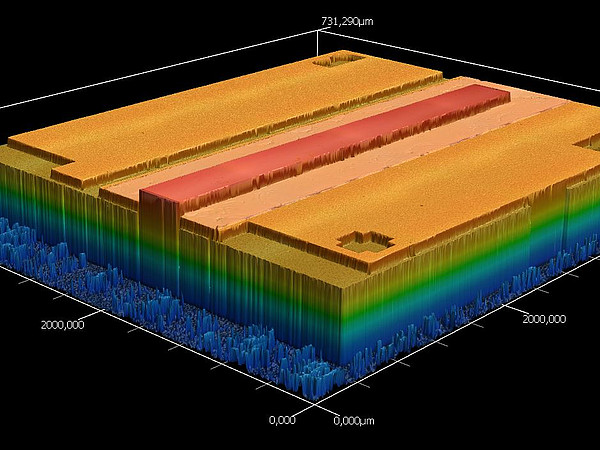

A flexible, future-proof solution was needed that would cover the entire spectrum of current and future requirements in the production of diode lasers, and potentially other applications. It was important not to sacrifice the high placement accuracy and process stability required at the expense of throughput.

A solution right under your nose

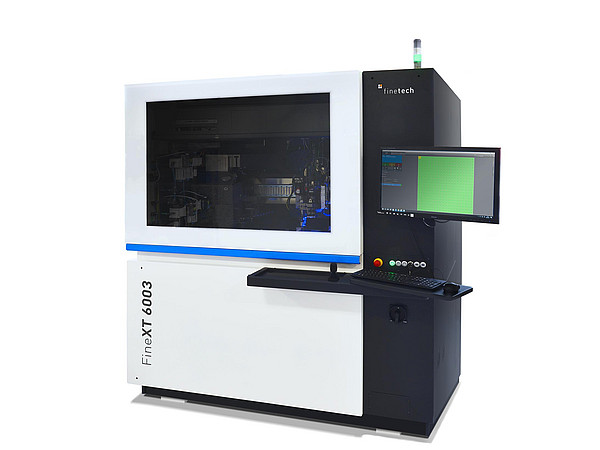

Just a few buildings away from the Lumics’ headquarters in Berlin-Marzahn, Finetech was working on an automated multi-chip bonder that closely matched this requirement profile. The FineXT 6003 is a production bonder where UPH, technology flexibility and placement accuracy are not mutually exclusive. Since Finetech already had an excellent reputation at Lumics as an equipment specialist for diode laser soldering and eutectic soldering, and because of the close proximity to each other, contact was quickly established. Together, they agreed on a one-year collaboration to further develop the automated die bonder in a live manufacturing setting at Lumics. The FineXT 6003 was gradually integrated into production during the trial phase.

The image recognition of the Finetech automated machine offers numerous new functions and enables completely different approaches. The bonding software, which provides centralized management and control of all machine components and processes, is much more advanced and versatile compared to Lumics’ previous machine. Lumics was able to rely on Finetech’s experience when it came time to gradually convert the existing assembly processes over to the FineXT 6003, and benefited from its extended possibilities and freedom in process design.

“Process repeatability is excellent. And all process parameters are monitored in real time, which provides pertinent information for process development. For example, the force characteristic curve indicates the melting point of the solder and therefore sets the required heating temperature and process duration for a component.”

Manager Backend Production, Lumics GmbH

Simultaneously, the field work at Lumics gave Finetech’s product developers valuable feedback in the further development of the die bonder. Both companies were able to learn a lot from each other during this collaboration and used this knowledge to bring the machine and the target applications to a new level.

The work also included the development of customer-specific tools for automatic diode laser soldering. In addition to self-balancing gimbal tools, the Lumics tools were primarily low-force and spring-loaded along the Z-axis. They require no additional touchdown force adjustment and enable shorter process times while maintaining placement accuracy and precise force control.

Continuous operation with maximum reliability

After a year of testing and further development, Lumics received a FineXT 6003 featuring a completely redesigned bond head as well as an additional Handling Module and Dispense Module. A new Substrate Heating Module with motorized Process Gas Module was added to provide an inert process environment for stable soldering results. The dimensioning of the motion axes were slightly adjusted and all process cameras were equipped with three-color light.

Since then, the multi-chip bonder has been in smooth, continuous operation. Lumics uses the machine for both pre-production (pre-sorting twisted submounts from 4-inch waffle packs into smaller waffle packs) and for automatic assembly of diode laser assemblies onto flat packs. With hundreds of units produced per week now, the production scale has increased significantly, and the Finetech machine still has capacity for additional assembly tasks, such as diode laser soldering onto the submounts.

Since virtually no manual intervention is required within the batch run, operators can now devote more attention to other work. Also, the 3 µm placement accuracy is reliably achieved and guarantees reproducible results, even in very demanding automatic assembly processes.

“With the FineXT 6003, most processes are now fully automatic. And thanks to the larger work area, the system can be loaded with significantly larger batches. For our operators, this means time savings of up to 90 percent, depending on the product.”

Manager Backend Production, Lumics GmbH