How Finetech assisted the National Nanotechnology Research Center (UNAM) in Turkey during the COVID-19 pandemic to retrofit and successfully deploy their existing FINEPLACER® system for a demanding ultrasonic flip-chip bonding application.

Bilkent University UNAM leads high-impact R&D projects in the fields of nanoscience, nanotechnology, biotechnology and materials sciences. With the aim to generate impactful and useful knowledge as a “national laboratory” and with strong focus on enabling quality science, social benefits and global innovation, UNAM determines to create world-class R&D workforce, globally cutting-edge science and high value-added technologies.

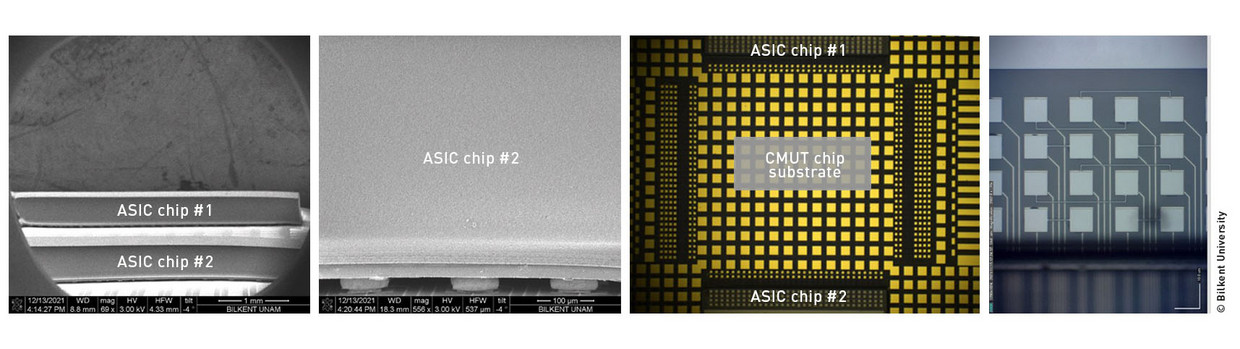

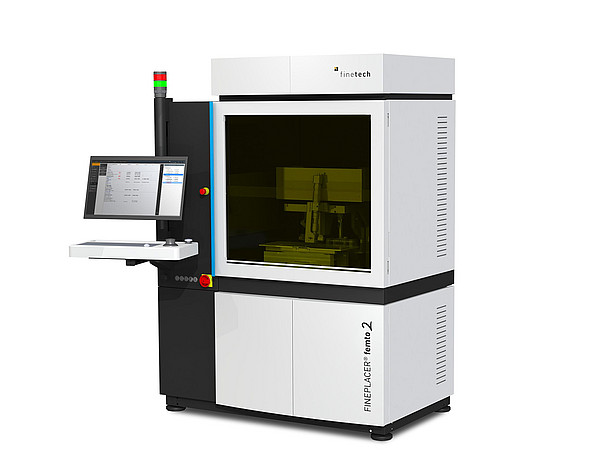

Back in 2014, UNAM acquired a FINEPLACER® micro assembly system to strengthen the research infrastructure, and also to make the tool available to users from academia and industry. Most recently, the die bonder was to be used as part of a TUBITAK (The Scientific and Technological Research Council of Turkey) 1003 Program (Primary Subjects R&D Funding Program) project for the development of a demanding ultrasonic flip-chip bonding application in the field of data communication between a CMUT array sensor chip and ASIC chips. However, there were two catches: first, the machine had not actually been specified for ultrasonic bonding capabilities when it was purchased, and second, the initially estimated force requirements per ball bump were believed to be insufficient for thermo-compression flip-chip bonding or ultrasonic flip-chip bonding of approximately 140 ball stud bumps made from gold wire.

Fast training

The principal investigator of the flip-chip bonding process development work package at the TUBITAK 1003 Program project, Dr. Mehmet Yilmaz, had very limited experience with Finetech equipment from his earlier studies. To get up to speed, Dr. Mehmet Yilmaz approached Finetech, and a training plan was developed together. Due to the COVID-19 pandemic, which ruled out on-site training, a graduate student of Dr. Yilmaz, Mr. Mehmet Halit Öztürk, and the 1003 Program project collaborator from Hakkari University, Dr. Fikret Yildiz, were trained extensively using video conference, telephone, TeamViewer and email. With dedicated and great effort from all involved, and due to the intuitive operation of the die bonder, Mr. Mehmet Halit Öztürk as the process owner, principal investigator Dr. Mehmet Yilmaz and collaborator Dr. Fikret Yildiz were quickly able to work independently on all micro assembly process steps on the machine.

Upgrade to ultrasonic

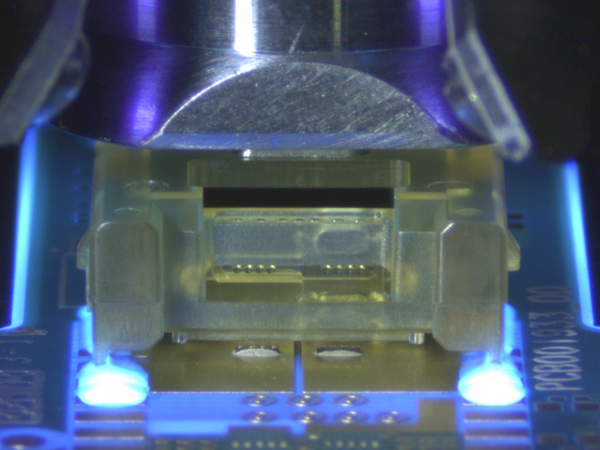

The flip-chip bonding application at the TUBITAK 1003 Program project is composed of materials that are very force-demanding (i.e. gold stud bumps from 25 micrometer diameter wires), heat-sensitive (i.e. ASIC chips), and are lacking conventional substrate pad and bump material compatibility (i.e. gold substrate pad with no under bump metallization). Bonding technologies such as soldering, adhesive bonding, or thermo-compression bonding, which are usually used for the assembly of chips with many stud bumps, are therefore assumed unsuitable as first options. Instead, thermo-sonic bonding, a combination of ultrasonic heating and conductive heating, was considered as a possible process approach. The fact that the machine at UNAM was not originally designed for ultrasonic applications is not an issue with a FINEPLACER® system. Thanks to the modular equipment platform, under suitable requirement conditions, new technologies and processes can be added and fully integrated into the system (both on the hardware and software sides) on-site via appropriate expansion modules, even years after purchase. This enables flexible and future-proof retrofitting and upgrading during the entire service life of the machine and is useful when application requirements change, which tends to be the “rule” rather than the exception in R&D environments.The application in the TUBITAK 1003 Program project is very demanding due to high co-planarity requirements, and the assumed narrow process window. In addition, special technical challenges arise due to the high number of stud bumps in combination with an ultrasonic process. Finetech was able to provide comprehensive support thanks to the process know-how of the engineering team that was gained over the last 30 years. Finetech also significantly helped with the development of a customized ultrasonic tool as well as a customized fixture for the substrate chip to focus the ultrasonic power to the region where it is exactly needed. In this phase of technical consulting support and process development, all possible digital communication channels were used due to the COVID-19 situation. Dr. Yilmaz particularly appreciated the access and personal communication with his contacts at Finetech during this time.

“I really appreciated the access and personal communication with my contacts at Finetech. Despite the COVID-19 restrictions, they went out of their way to get us started with our challenging ultrasonic flip chip bonding application.”

PhD, Principal Investigator, Bilkent University UNAM and Institute of Materials Science and Nanotechnology

The application in the TUBITAK 1003 Program project is very demanding due to high co-planarity requirements, and the assumed narrow process window. In addition, special technical challenges arise due to the high number of stud bumps in combination with an ultrasonic process. Finetech was able to provide comprehensive support thanks to the process know-how of the engineering team that was gained over the last 30 years. Finetech also significantly helped with the development of a customized ultrasonic tool as well as a customized fixture for the substrate chip to focus the ultrasonic power to the region where it is exactly needed. In this phase of technical consulting support and process development, all possible digital communication channels were used due to the COVID-19 situation. Dr. Yilmaz particularly appreciated the access and personal communication with his contacts at Finetech during this time.

Successful project start

In summary, despite the difficult conditions caused by the COVID-19 pandemic, process owner and graduate student Mr. Mehmet Halit Öztürk, Dr. Yilmaz, and Dr. Yildiz were able to become familiarized with the machine in a short time. Development of the challenging ultrasonic flip-chip bonding application was successfully initiated by retrofitting the existing machine and supplying customized hardware solutions. In addition, Finetech provided valuable engineering support and was able to successfully accompany Dr. Yilmaz and his partners through the start of the project.