Author: Dan Lilie

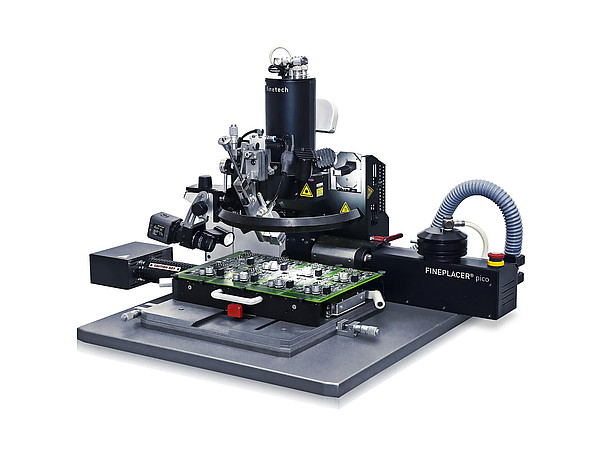

Abstract: Precise placement of a new solder ball array is called array reballing. This repair process is applied when saving valuable resources (and money) is crucial or when the value chain has to be extended. Array reballing is typically needed when a BGA has been misplaced on the placement line, when solder paste pressure has not been sufficient, or when the pads of the circuit board are oxidized and there is no contact through the solder balls anymore. These are the typical defects usually leading to the solder balls being replaced. But before new solder balls can be placed, the residual solder must be removed from the entire ball array. And then new solder balls can be placed onto the component. Critical are usually the complete and even removal of the residual solder as well as the remelting and the wetting behavior of the new solder balls. Qualified processes tailored to customer needs and products are essential for high quality results, especially for those components which usually would not be suitable for the reballing process.