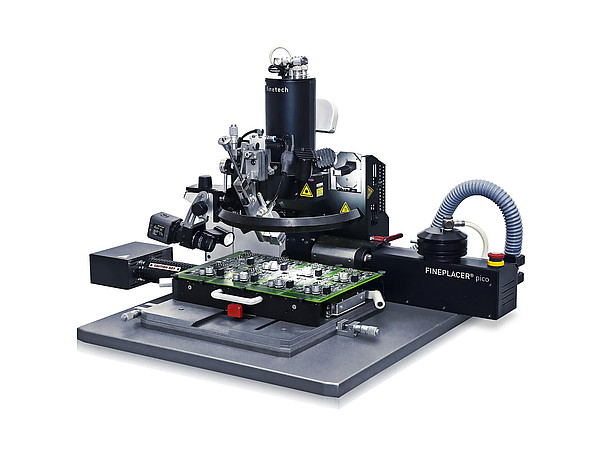

Author: Dan Lilie

Abstract: An accurate residual solder removal is an essential factor of success for most rework applications. In field, this is often done using solder iron and wick. Unfortunately, the quality of the solder removal strongly depends on the operator’s skills. Pads will be frequently torn off or the solder resist will get damaged. When looking ahead it is also evident that component sizes will keep shrinking and packing densities will get higher. This means that proper access to the residual solder will become more of a challenge. This is there Finetech’s solutions for contactless residual solder removal comes into play. They are suitable for virtually all SMD components in the market, from small passive resistors to large BGAs.