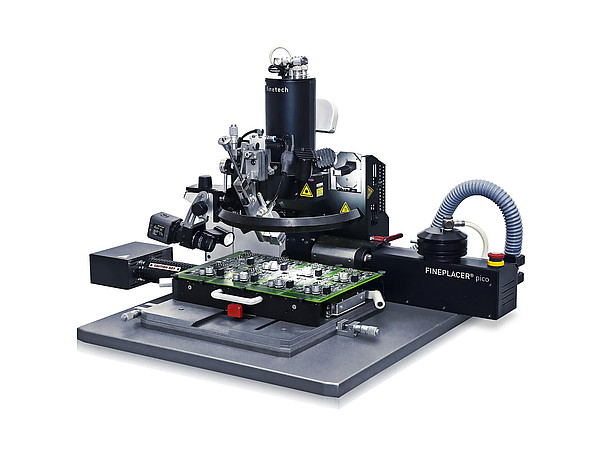

Author: Dan Lilie

Abstract: Flat packages such as QFNs (Quad Flat No-lead) or other MLFs (Micro Lead Frame) with outstanding thermal, inductive and capacitive characteristics (for example resulting in much shorter reaction times) are being increasingly incorporated into densely populated, space-saving assemblies. However, unlike BGA components, QFNs do not provide a solder ball array for SMD assembly but have to be soldered to the assembly with their contact pads attached directly to the metalized body (lead frames). This technology makes much higher demands compared to the handling of standard SMD components. Usually, QFN and MLF components have a mass pad which is especially hard to de-solder. Not only the heat is quickly dissipated into the board, but also the removal is critical due to adhesion forces of the liquid solder. The nozzle had to be constructed and handled in a certain way to achieve reliable results. Fresh solder paste also should be applied carefully; too much solder does not allow for the proper floating of the component into position.