Earlier this year, Finetech participated in the IMAPS Advanced Packaging for Medical Microelectronics Workshop in San Diego, and it did not disappoint.

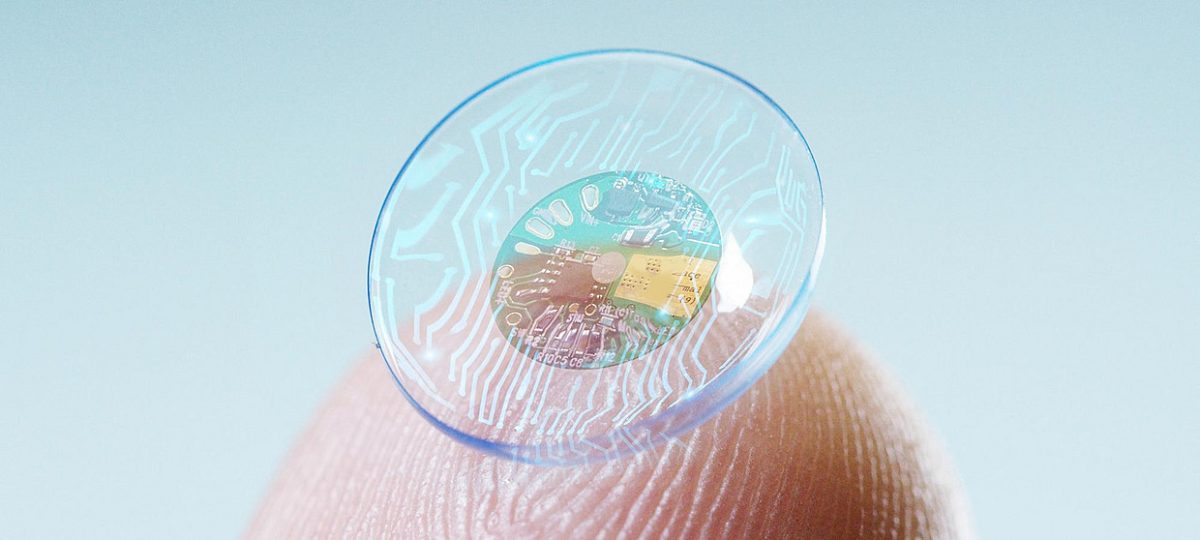

It was great to see that several technical presentations referenced Finetech in multiple, equally interesting bio-medical applications. A Lawrence Livermore National Labs presentation described the development of an artificial retina which utilizes semiconductor technology to deliver a bio-compatible electronic package containing the electronics for stimulating the retina. I also learned more about glucose sensing technology embedded onto a contact lens, where a small glucose sensor, in combination with a chip and antenna, are used to help diabetic patients wirelessly monitor their glucose levels. Other technical sessions discussed some of the challenges of bio-medical applications, including encapsulation and the process of getting FDA and other government regulation approvals completed and ready to manufacture in a higher volume.

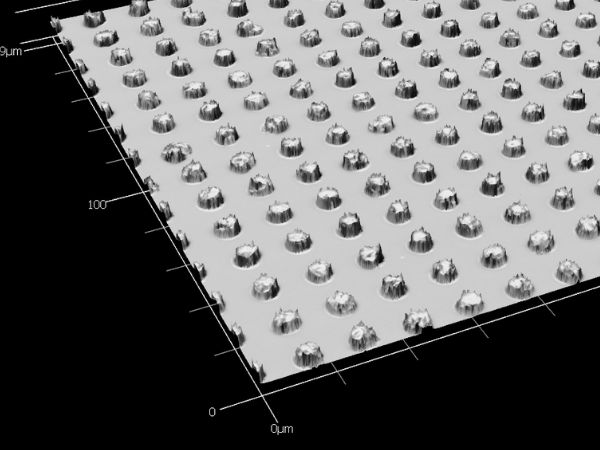

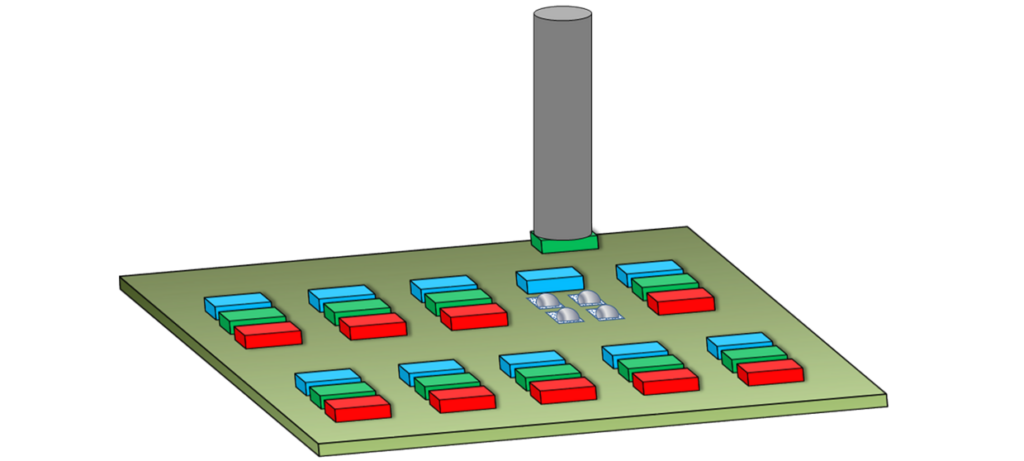

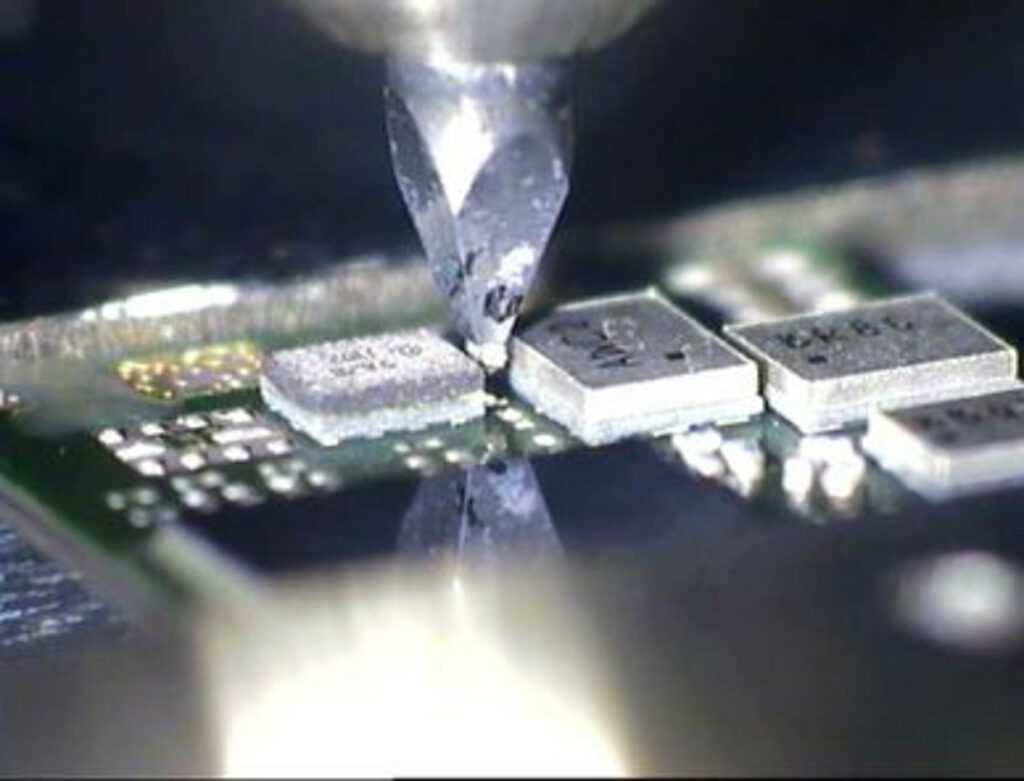

In 2018, Finetech’s die bonding technology helped accelerate catheter capabilities. A catheter is defined as a thin tube made from medical grade materials that is inserted into the body to perform a wide range of surgical or diagnostic functions – they access the inner reaches of our bodies without painful, invasive open surgeries. The solution consisted of bonding multiple ultrasonic transducers onto a flex cable that was approximately 1.5 meters in length. These small MEMS die are bonded and bundled into a catheter, with each die providing a different function. As you can imagine, anything of that length will likely be inserted through an artery in the leg and moved up to the heart. Handling a flex circuit of that length always proves to be a challenge. Most equipment on the market was developed to handle more traditional, rigid printed circuits boards (PCB’s). Flex PCB’s are not “new” technology but today’s cutting-edge applications – like a smart catheter that shows real time 3D rendering of the organs inside the body – is truly evolutionary, not revolutionary.

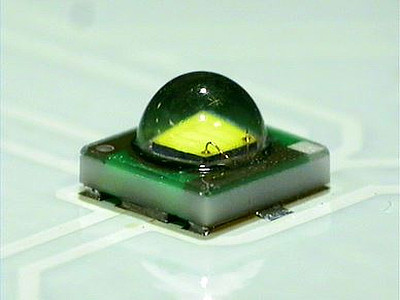

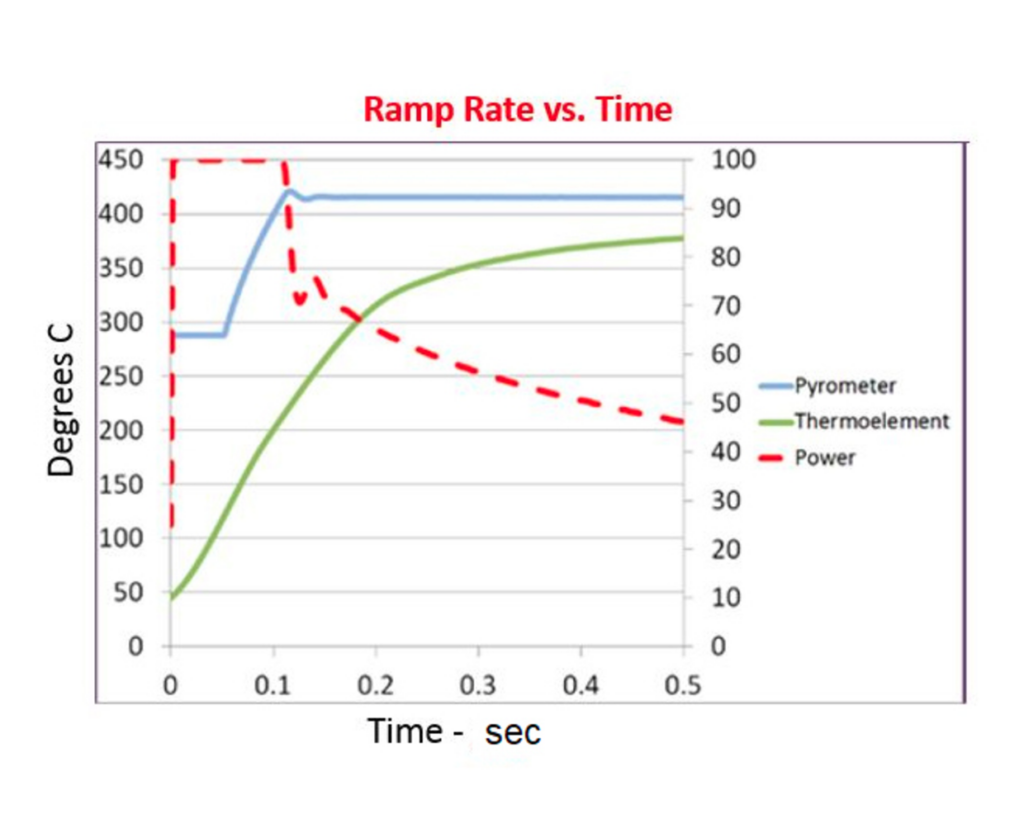

Die bonding to flex or other types of circuits is not at all foreign to Finetech. Challenges always come into play when customers develop a new product utilizing established processes, like Thermo-Sonic or Thermo-Compression bonding but include a new “twist”. Reviewing a Bill of Material (BOM) is always our first step to help our customer understand what is and what’s not possible in terms of process and product development.

Our die bonding expertise covers a full spectrum of applications and bio-medical is one of many business sectors that require precise die attach. Is bio-medical really any different from say, a LiDAR application? From our perspective, sure, but many similarities cross over the industry segments. Our first priority is to help customers understand process related solutions so they can be first to market. First to market is a big deal for investors and more importantly, for patients needing medical technology solutions. We are always up for a new challenge and ready to provide the time sensitive support often needed in the medical market.

05/09/2019, created by: Robert Avila