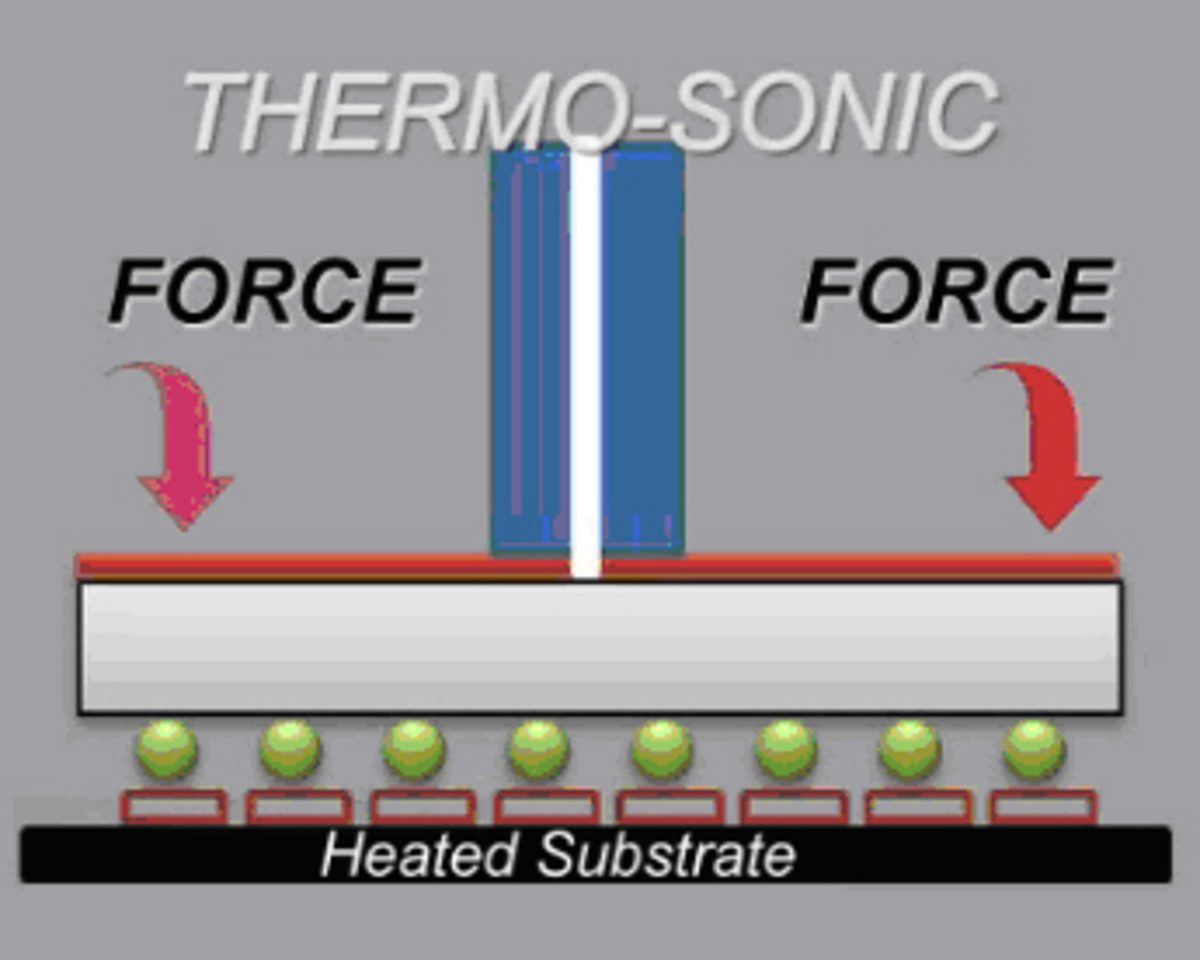

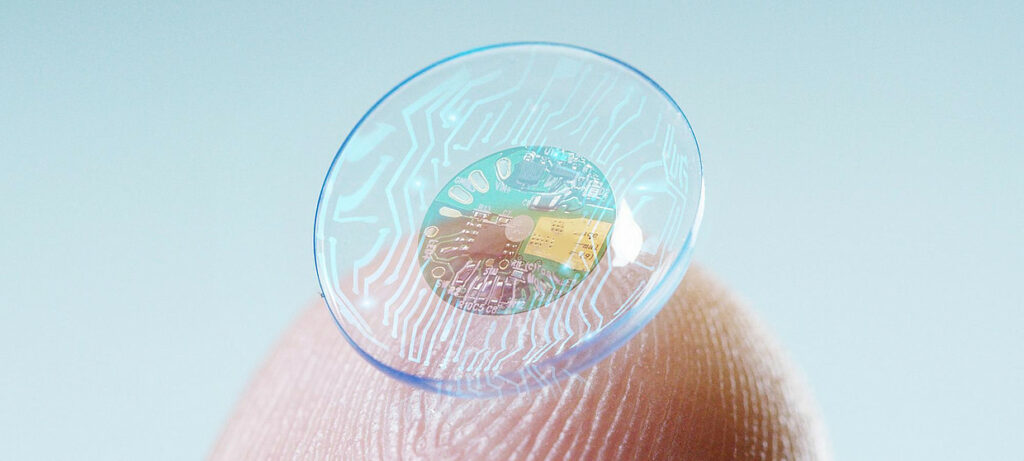

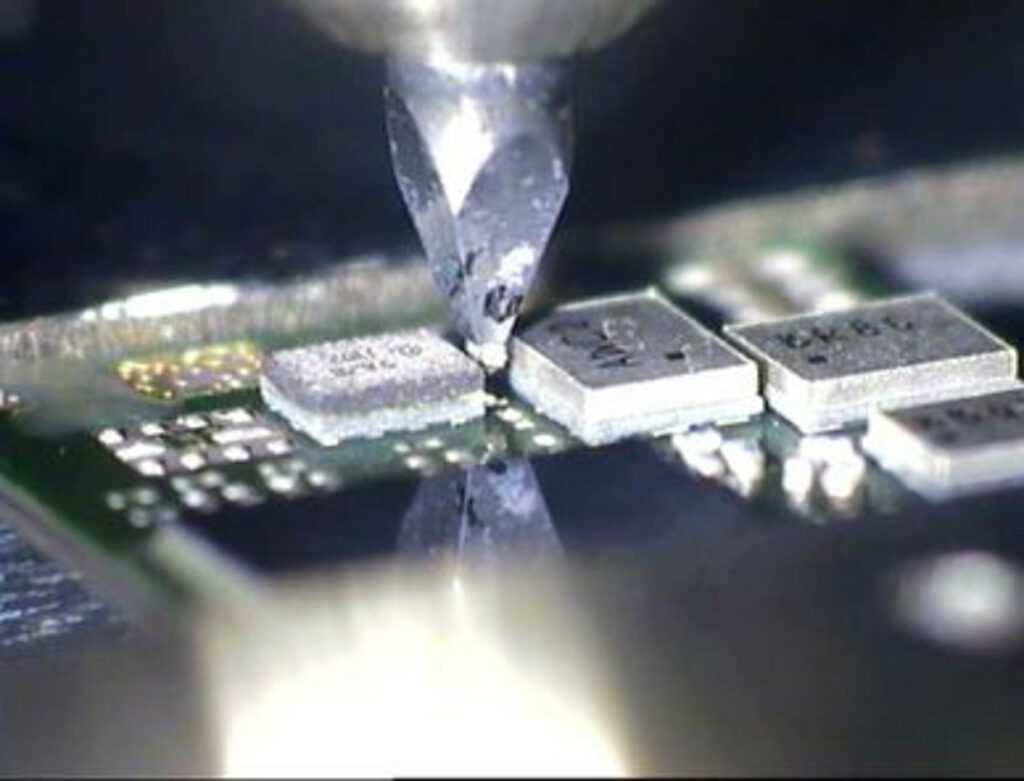

In my last blog I wrote about the challenges involved with thermo-sonic bonding of large die. Thermo-sonic bonding of smaller die presents similar process issues – balancing the ratio of vacuum over force/energy/time.

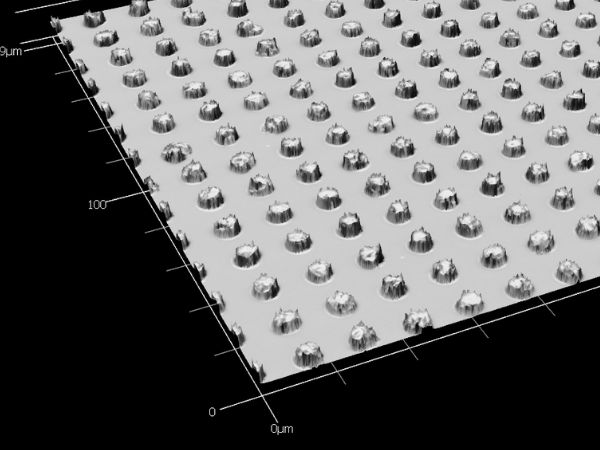

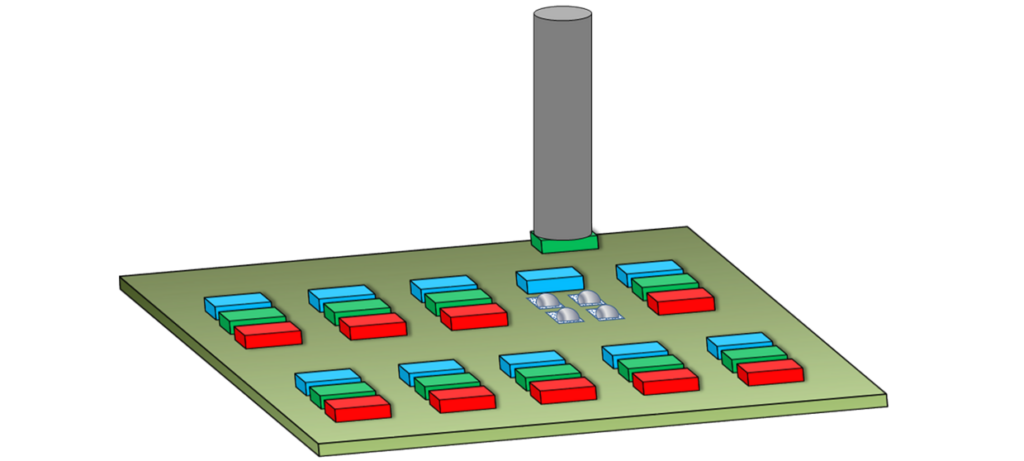

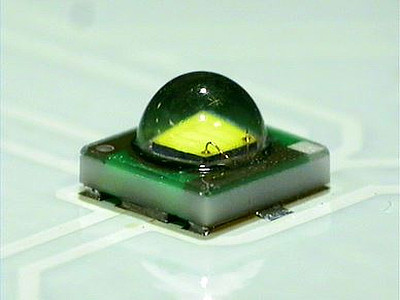

As the die size decreases (2 x 2mm for example), so does the vacuum hole in the die collet. Creating the correct ratio of vacuum strength relative to die size is tricky. The overall vacuum area can be increased by making the vacuum hole diameter larger, but on a die of small proportions doing that creates another problem. As the vacuum hole increases, the area in which force is applied decreases and on a small die, there is little room for force to be applied to begin with. Making the vacuum hole smaller allows more force to be applied over the die but creates a problem if the vacuum pressure is not enough to secure the die to the die collet during the bonding process. Just as with large die, this results in no energy being transferred from the interconnect of the die to the substrate. It’s very important that the collet be designed precisely relative to die size vs. vacuum diameter. The key to successful thermo-sonic bonding is all about balance.

Finetech has years of experience in calculating the correct process parameters for both large die and small die to help its customers achieve a repeatable process. Feel free to contact me with any questions.

09/24/2014, created by: Robert Avila